CDPL glass batching system

Product Details

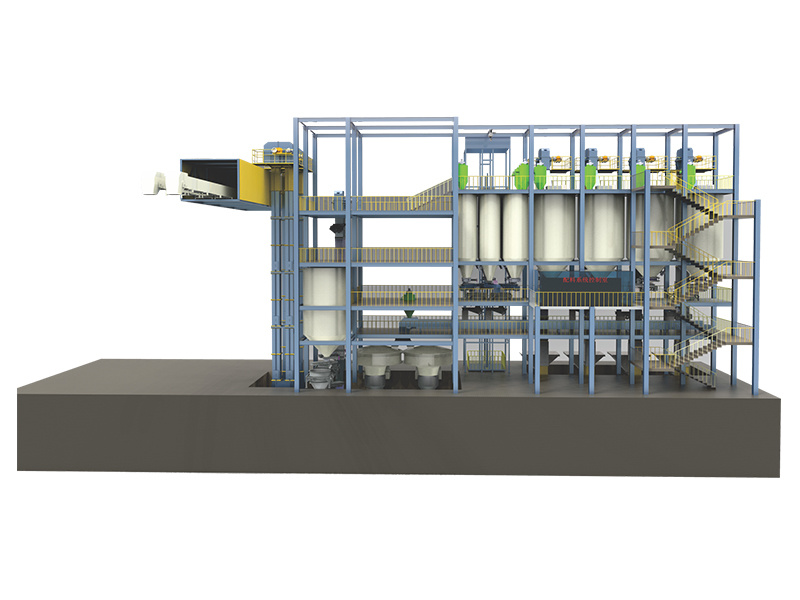

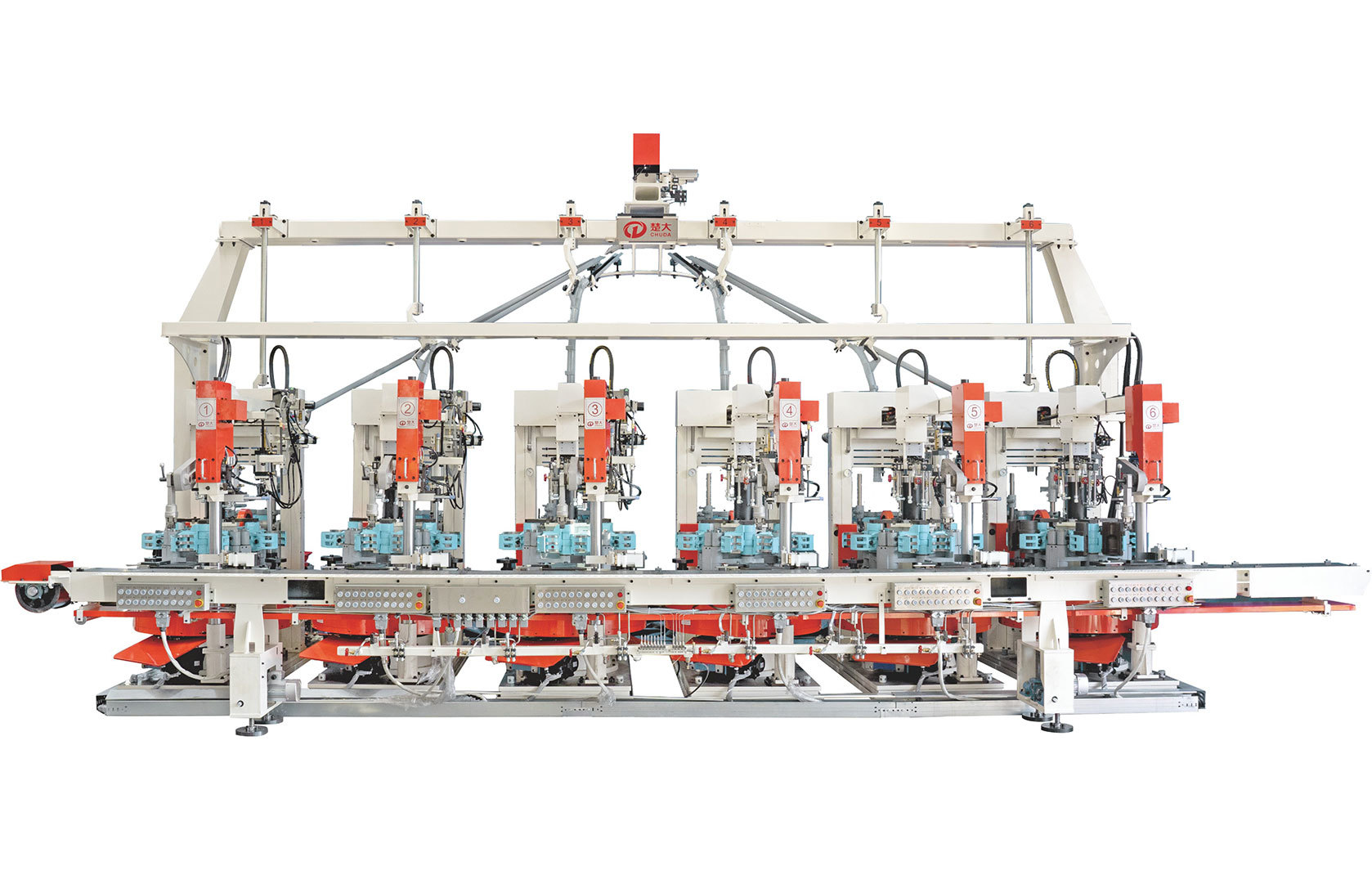

CDPL-1型——适合为出料量30~80吨/天的单个或多个窑炉供料

CDPL-1 Batch system—suitable for feeding of single/multiple furnace with a capacity of 30-80 tons/day

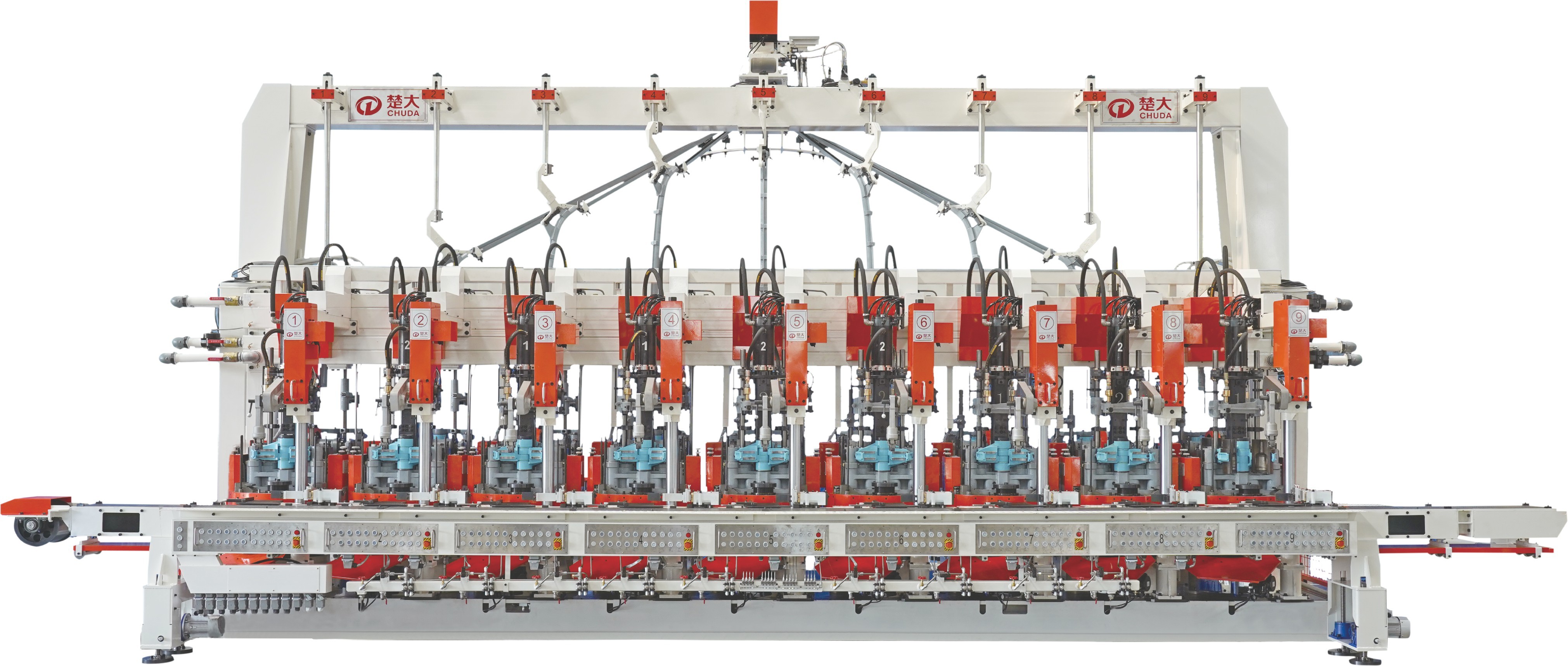

CDPL-2型——适合为出料量60~200吨/天的单个或多个窑炉供料

CDPL-2 Batch system—suitable for feeding of single/multiple furnace with a capacity of 60-200 tons/day

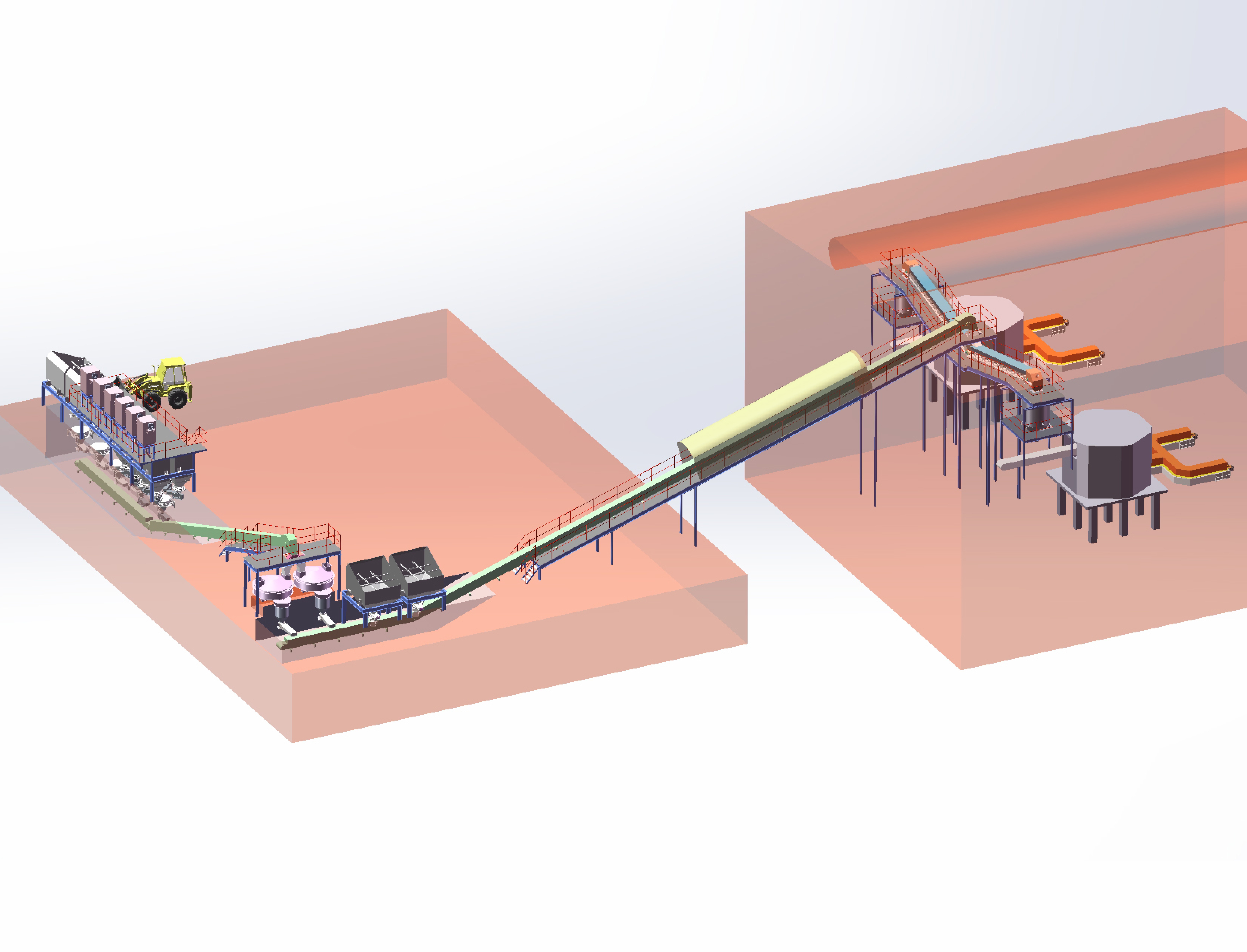

CDPL-3型——适合为出料量150~400吨/天的单个或多个窑炉供料

CDPL-3 Batch system—suitable for feeding of single /multiple furnace with a capacity of 150-400 tons/day

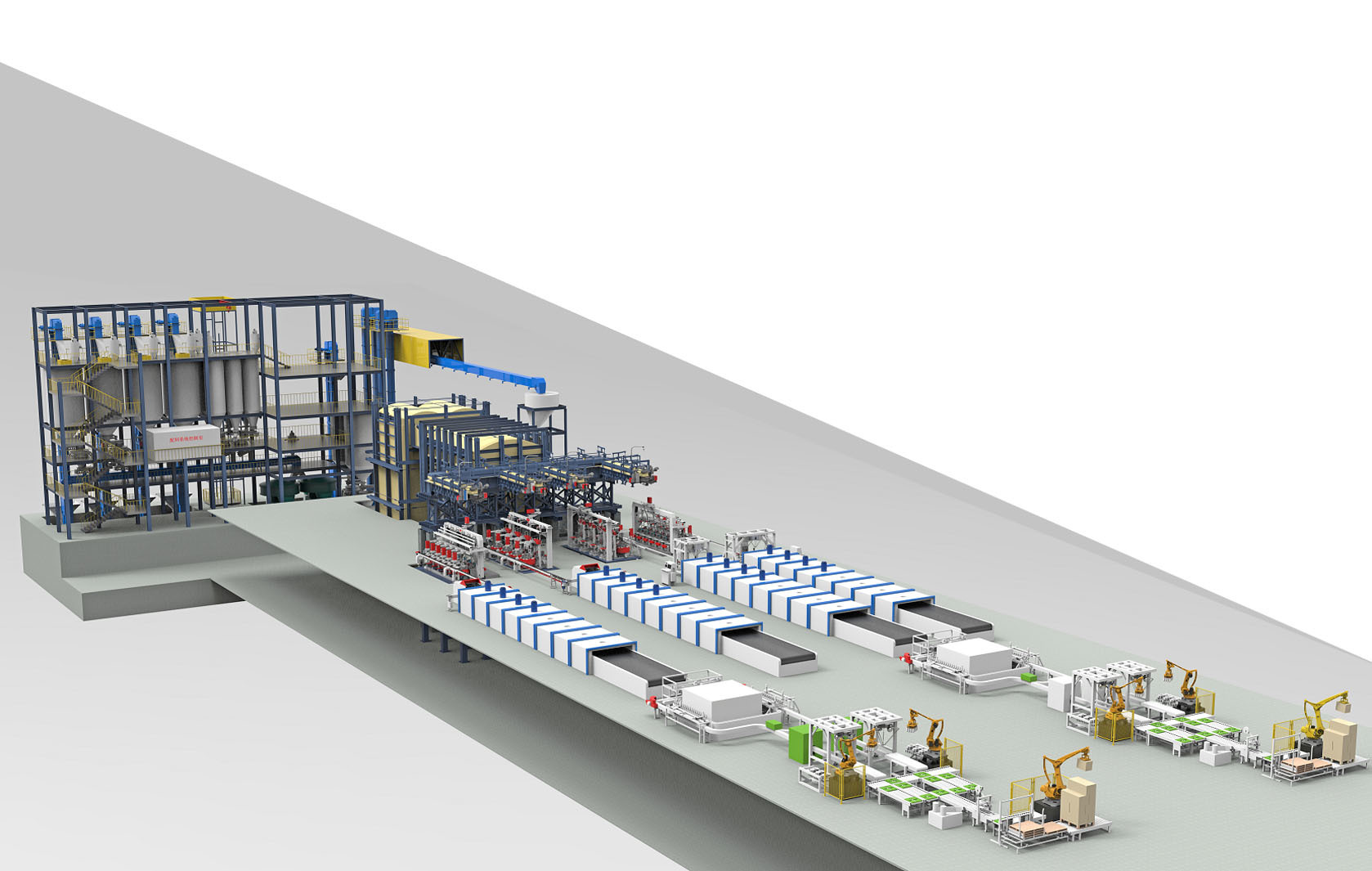

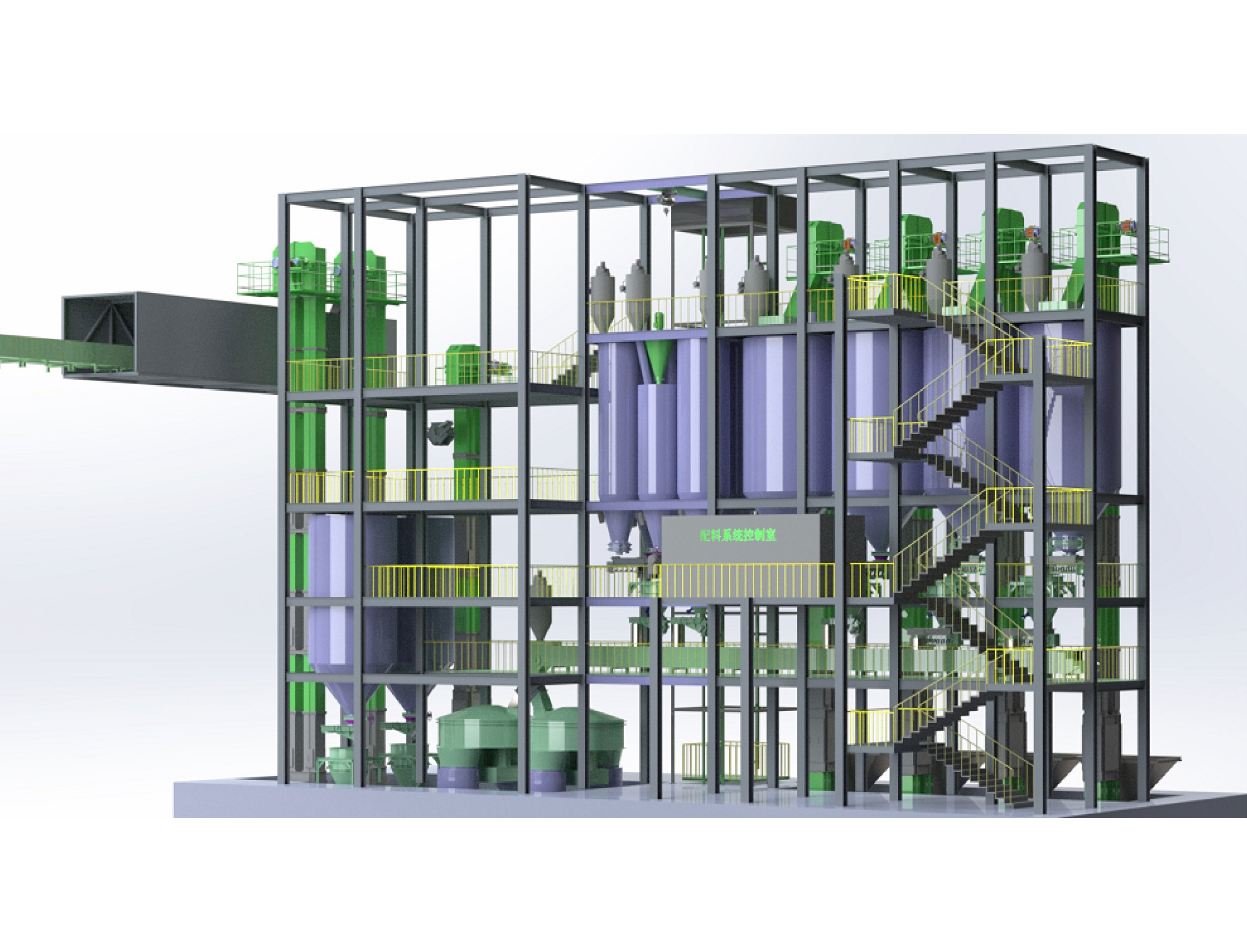

CDPL-4型——适合为出料量300~1000吨/天的单个或多个窑炉供料,原料配料整体解决方案

CDPL-4 Batch system—suitable for feeding of single/multiple furnace with a capacity of 300-1000 tons/day, comprehensive solutions to raw matenals and batch

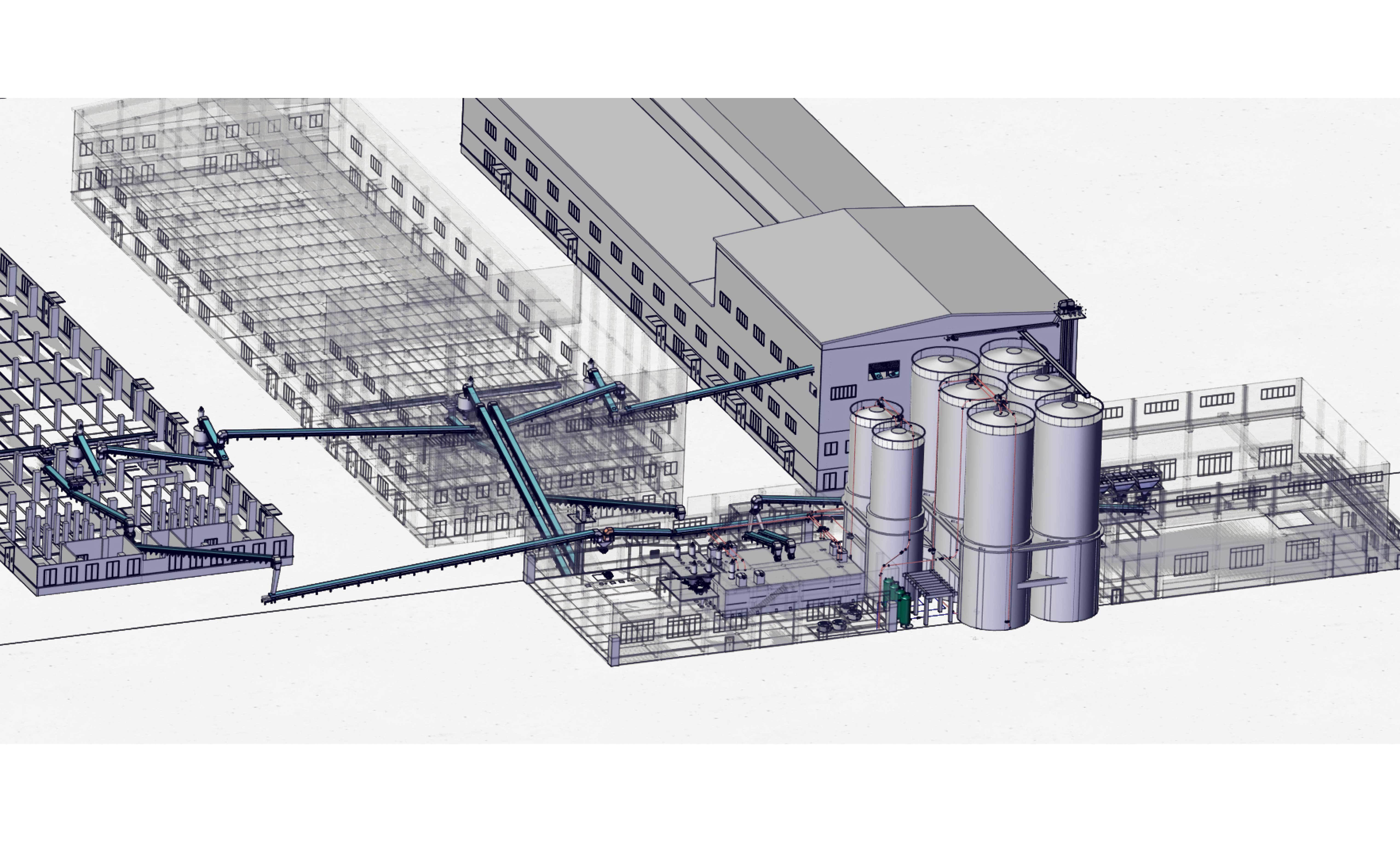

DESIGN & TECHNOLOGY

楚大智能为客户量身设计原配料系统全过程解决方案。

Chuda Intelligent customized design the

comprehensive solutions of raw materials batching system for customers.

技术团队采用3D数字化研发管理平台,先进的可视化、仿真和数据管理,确保项目目标的达成。

The technical team adopts 3D digital R&D management platform, advanced visualization,

simulation and data management to ensure the achievement of project objectives.

广泛应用于30—1000吨瓶罐、器皿、微晶、电子、玻纤、医药、建材、光伏等行业,国内外超过200余项项目设计、施工、服务经验。

Widely used in industries such as glass containers, glasswares, glass ceramics,

electronics, glass fiber, pharmaceuticals, building materials, photovoltaics with a capacity of 30-1000TPD,

of which the implementation experience has covered more than 200 projects.

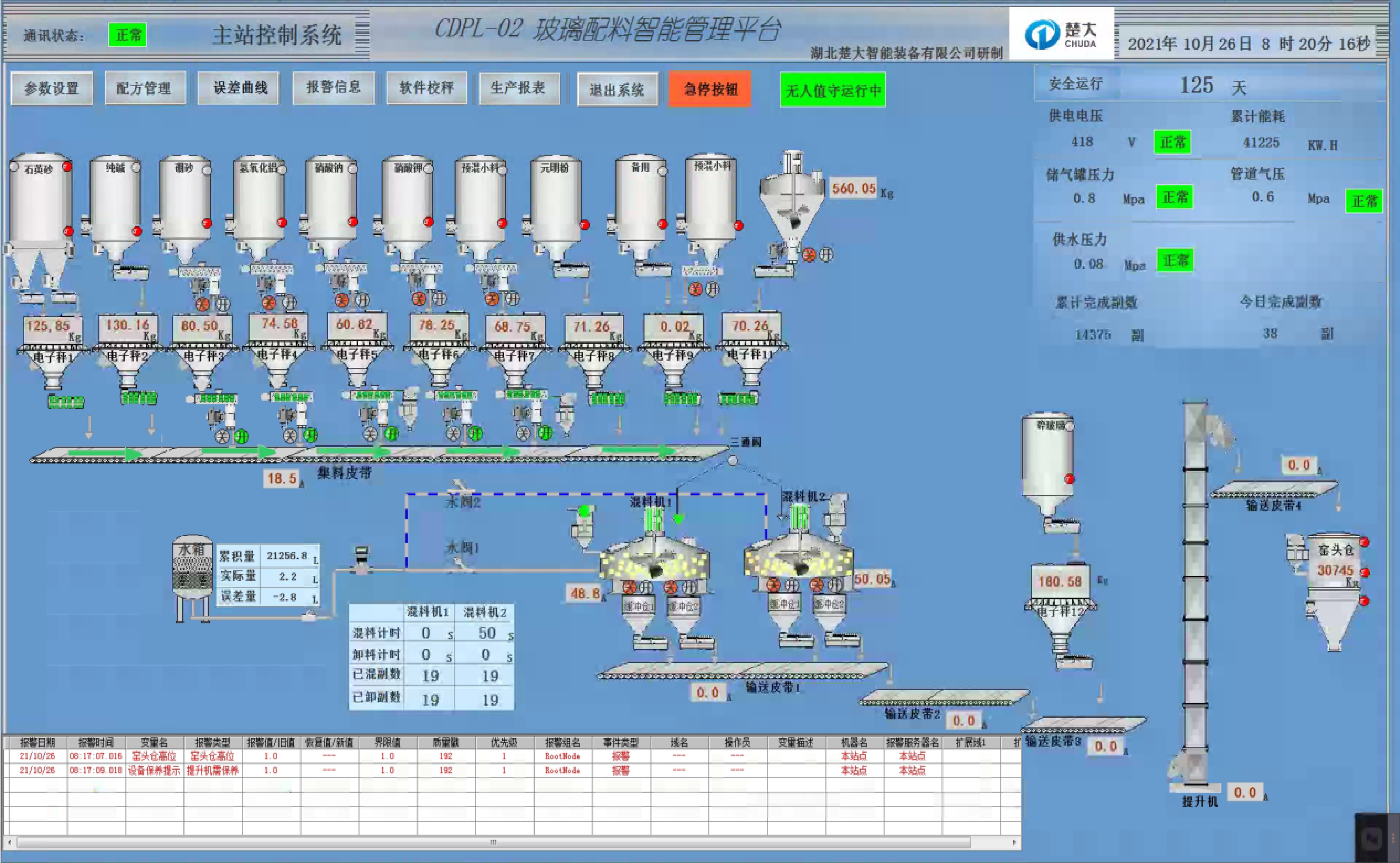

ELECTRONIC CONTROLS & EQUIPMENT

楚大智能提供具备高精度称量、高效输送和均匀混合功能的自动配料控制系统,依据配料工艺特点要求,自动化配料系统遵循安全可靠、洁净环保、称量精准、简单操作、方便维护、智能化程度高的原则进行设计和选型。

与Siemens、Schneider、ABB、WAM等知名供应商密切合作,把握最新的控制技术发展方向,提升用户体验。

CHUDA provides an automatic batch control system with high-precision weighing efficient

conveying and uniform mixing functions. Based on the characteristics of batch process,

automatic batch system from CHUDA is designed and selected according to the principles of safety and reliability,

cleanliness and environmental protection, accurate weighing, easy to operate and maintain.

Cooperating with suppliers such as Siemens, Schneider, ABB, WAM to set the latest development

direction of control technology and enhance user experience.

| 我们提供 WE SUPPLY | |

| 电气硬件设计 Electrical Hardware Design |

电气软件开发 Electrical Software Development |

|

安装调试 Installation & Commissioning |

售后服务 After-sales Service |

| ※配料现场无人值守功能 Unattended Function | |

| ※手机APP远程操作和提醒功能 Remote Operation And Reminder Function By APP | |

| ※5G工业互联网远程运维服务 Remote Operation And Maintenance Service By 5G Industrial Internet |

|

| ※为选配功能 Optional | |

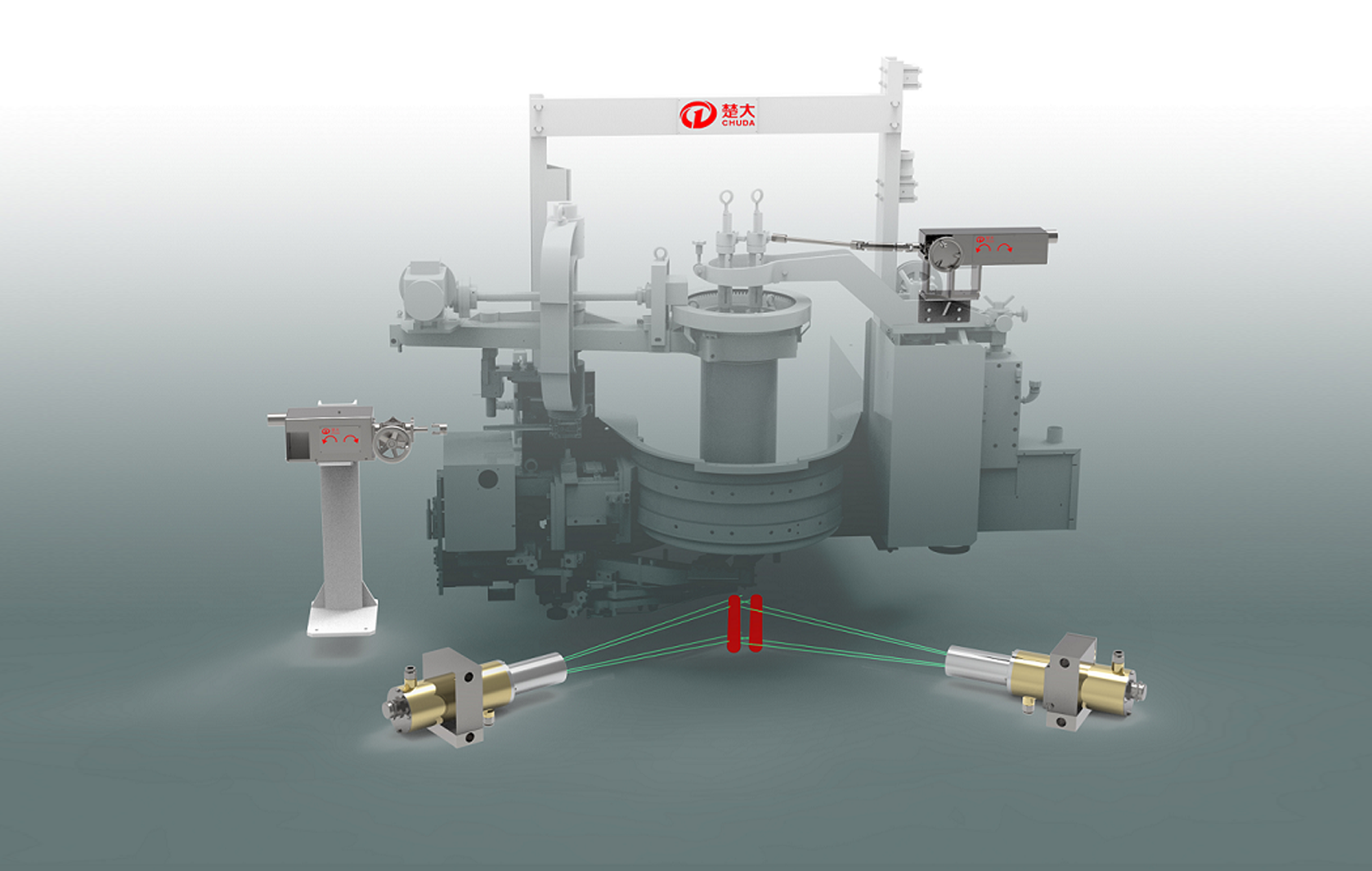

RELATED EQUIPMENT OF BATCH SYSTEM

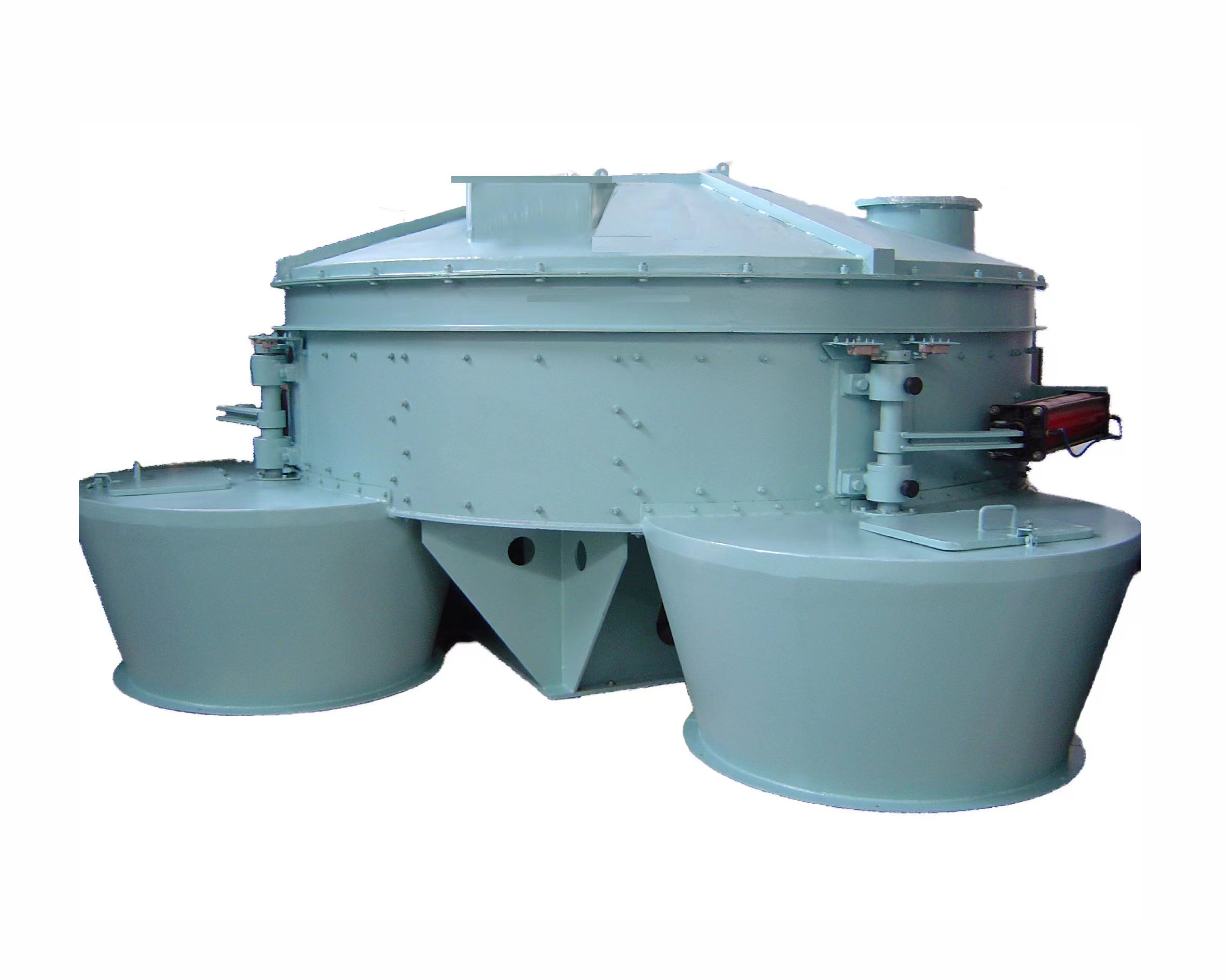

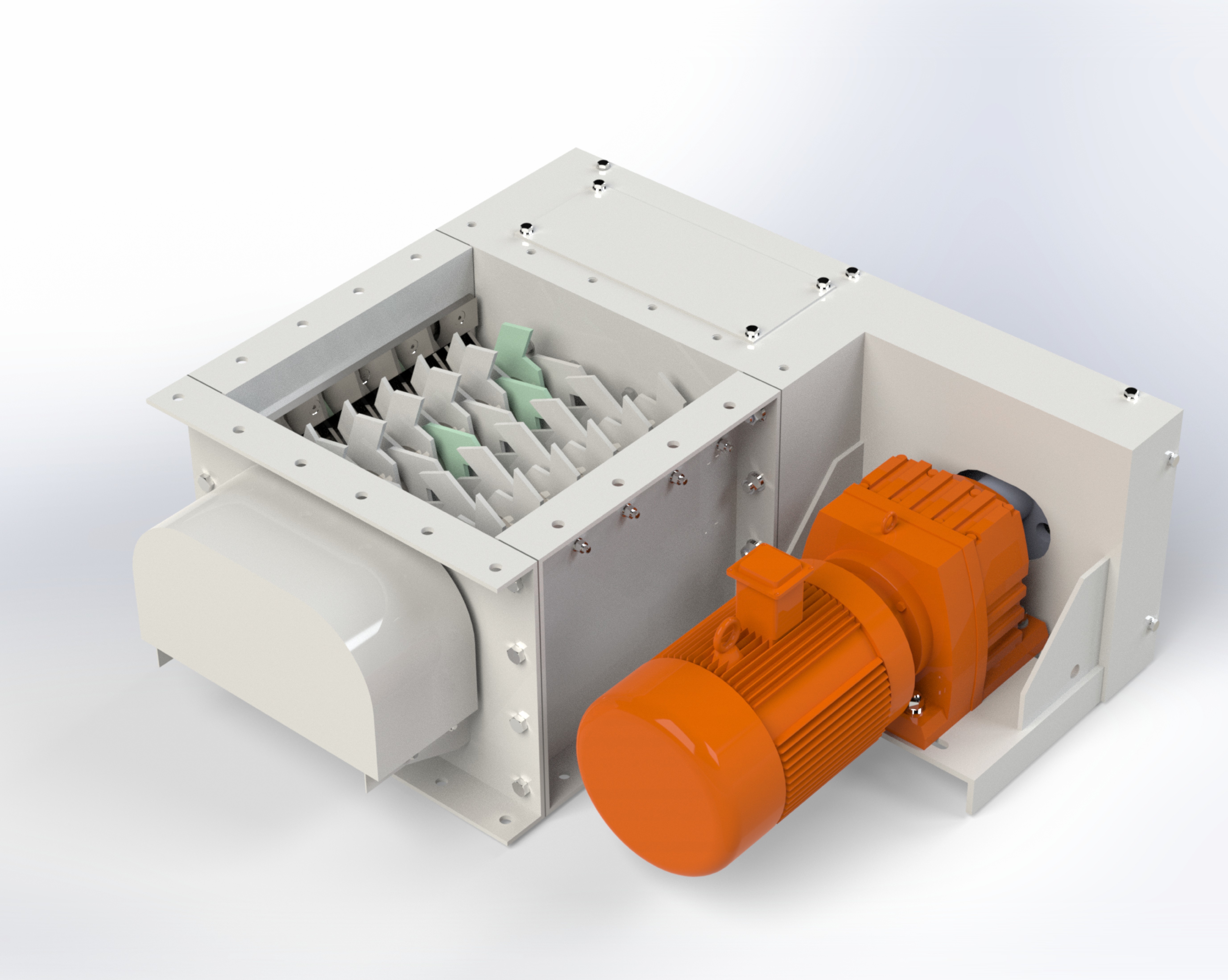

强制式混合机

Forced Mixer

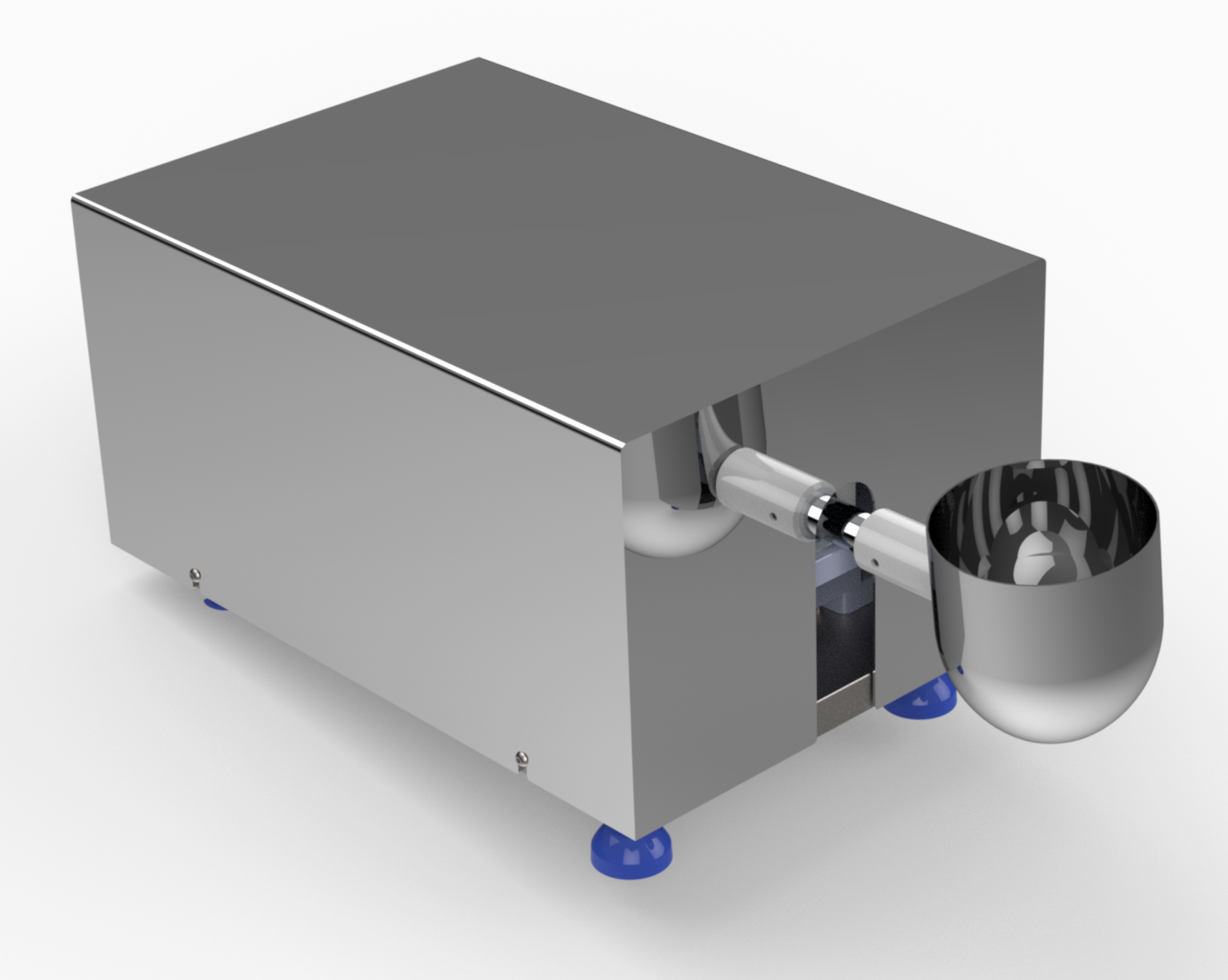

高精度微量称

High-precision Micro Scale

粉料破块器

Powder Block Breaker

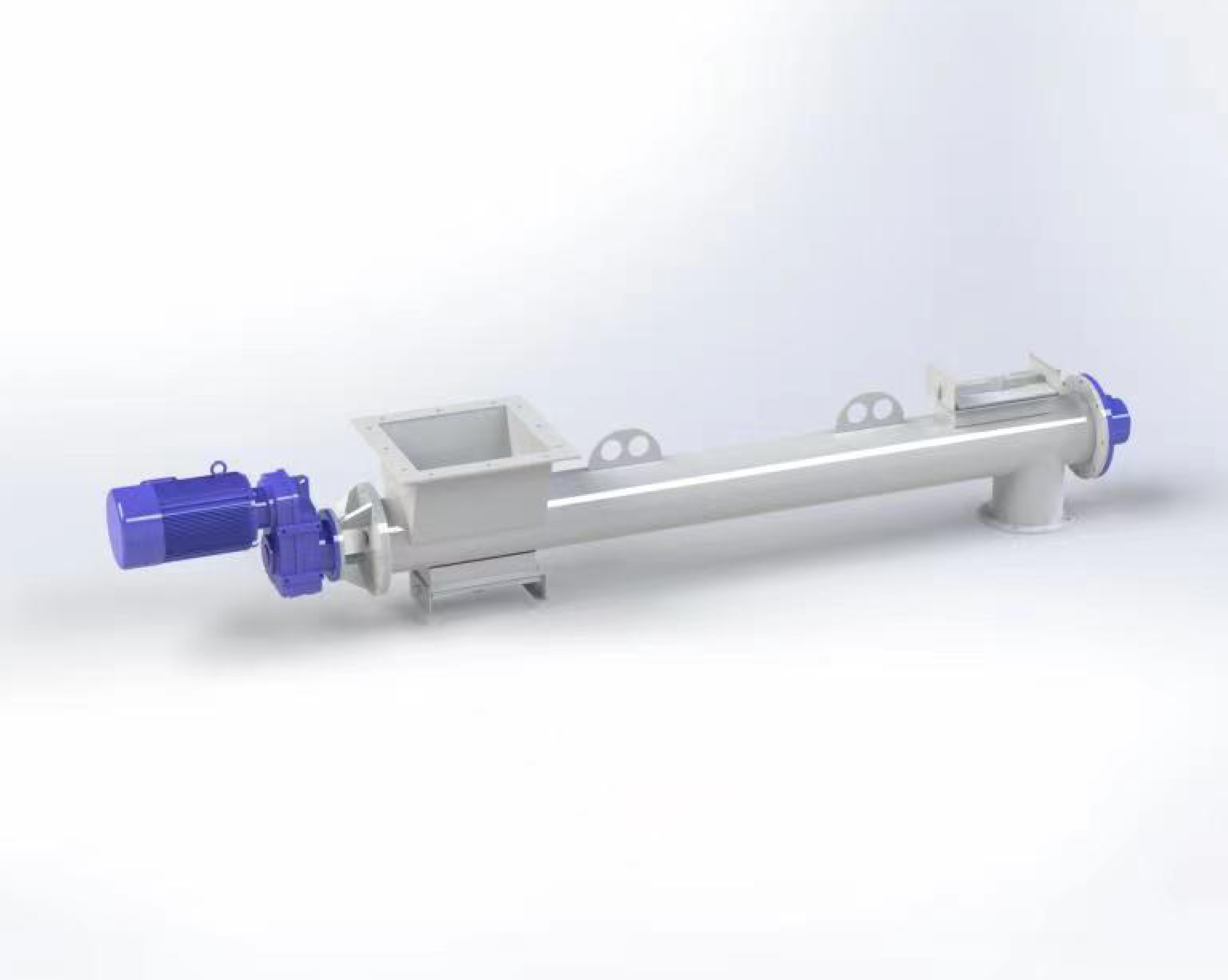

螺旋给料机

Screw Feeder

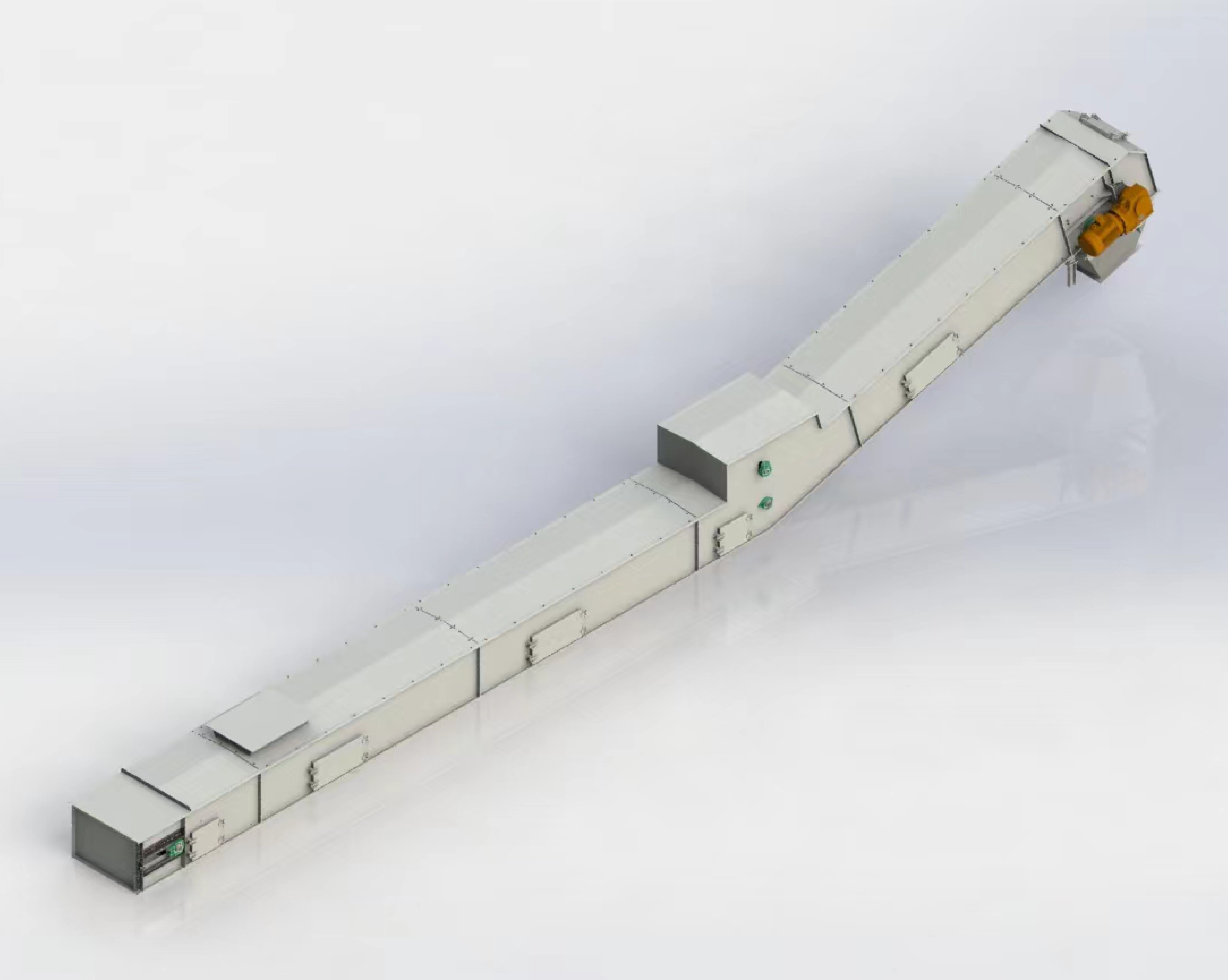

斗式提升机

Bucket Elevator

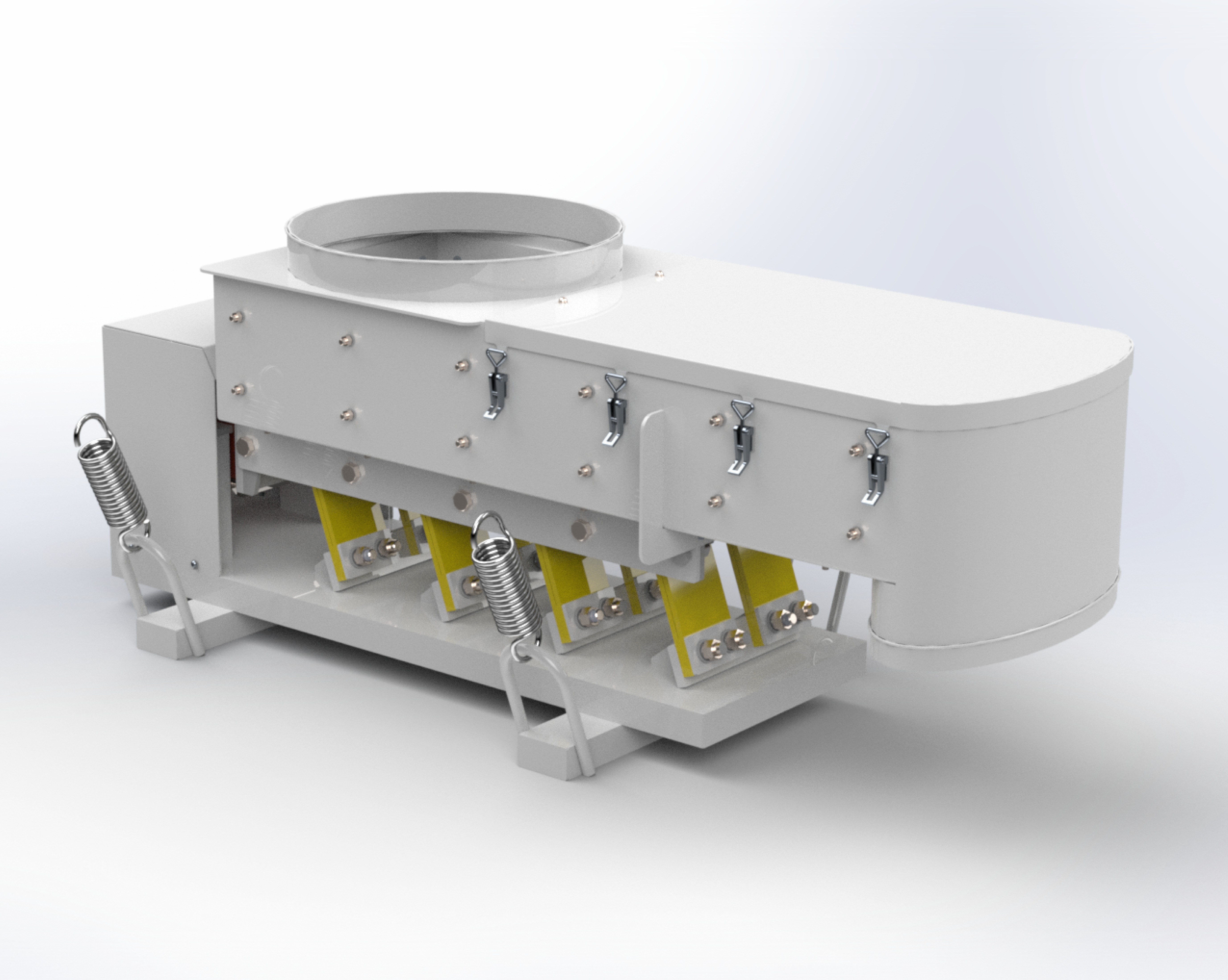

DMA系列电磁振动给料机

Electromagnetic Vibrating Feeder

带式输送机

Belt Conveyor

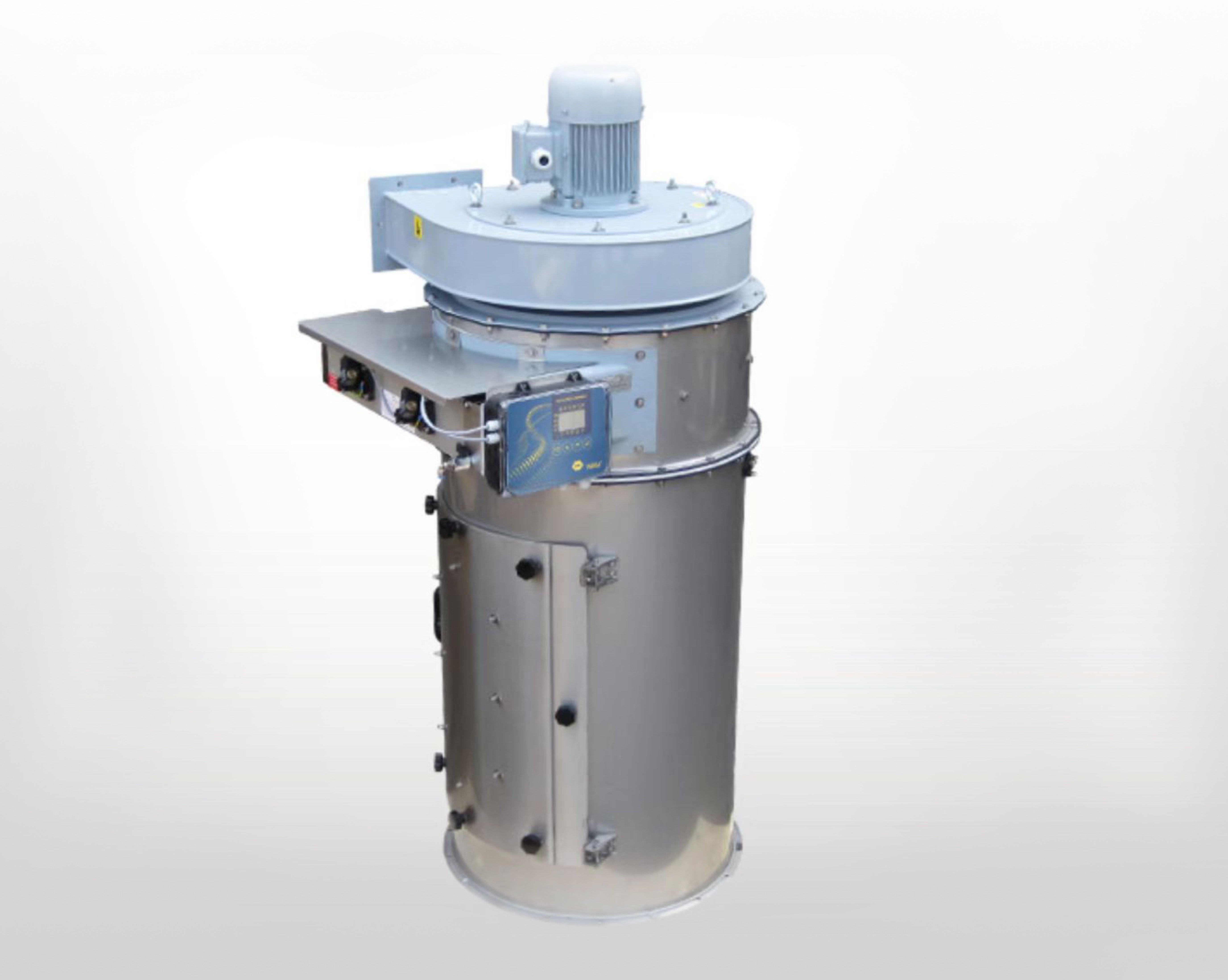

脉冲式除尘器

Pulse Dust Collector

在线水分测试仪

Moisture Tester

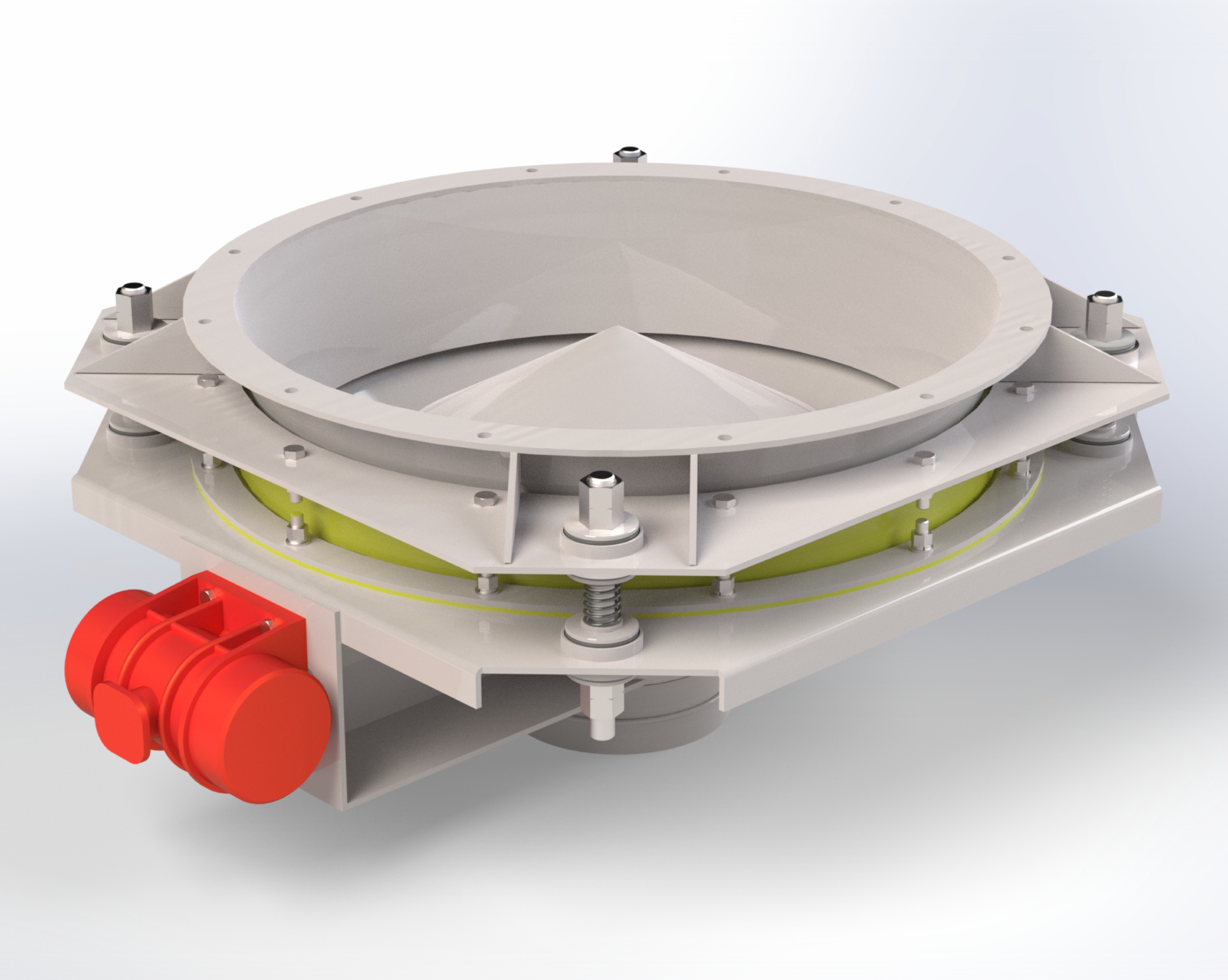

GD系列惯性振动料斗

Inertia Vibrating Hopper

GLASS BATCH PLANT PROJECT

Online Inquiry

If you have any suggestions or feedback on our service, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.

WeChat Public Number

Hubei Chuda Intelligent Equipment Co., Ltd.

Telephone:0724-2498136

E-mail:fiona@chuda.cn

Production Base: No.1 Jingnan Avenue, Duodao District, Jingmen City, Hubei Province

Copyright: Hubei Chuda Intelligent Equipment Co., Ltd. This website has supported IPV4 / IPV6 bidirectional access

Website construction:China Enterprise Power Yichang

SAF Coolest v1.3 设置面板 MPFSX-ZHXV-UQAAE-ZXF

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page