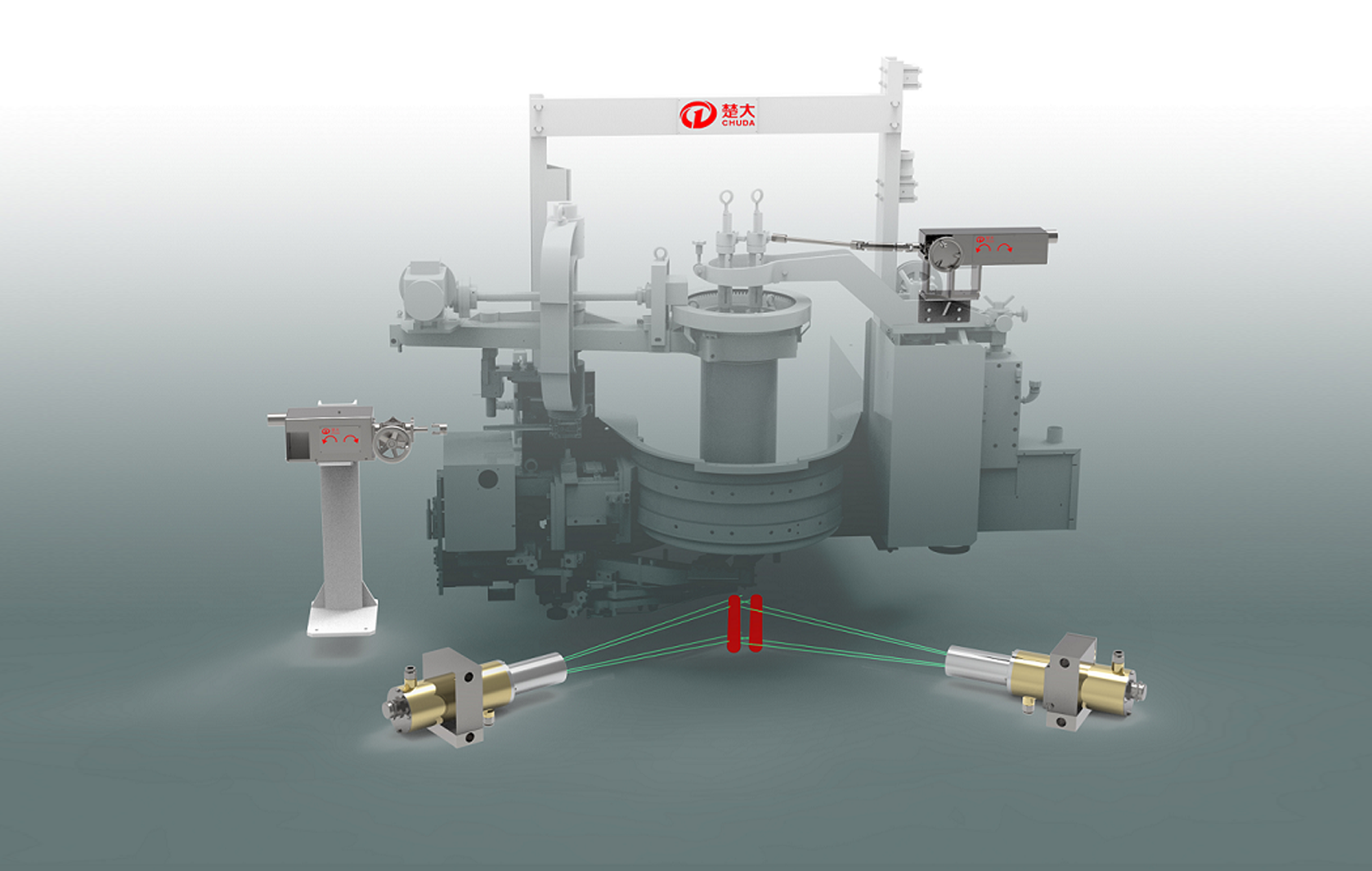

Binocular Vision Material Weight System (CBGW Series)

Product Details

GOB WEIGHT CONTROL SYSTEM(CBGW SERIES) TYPES

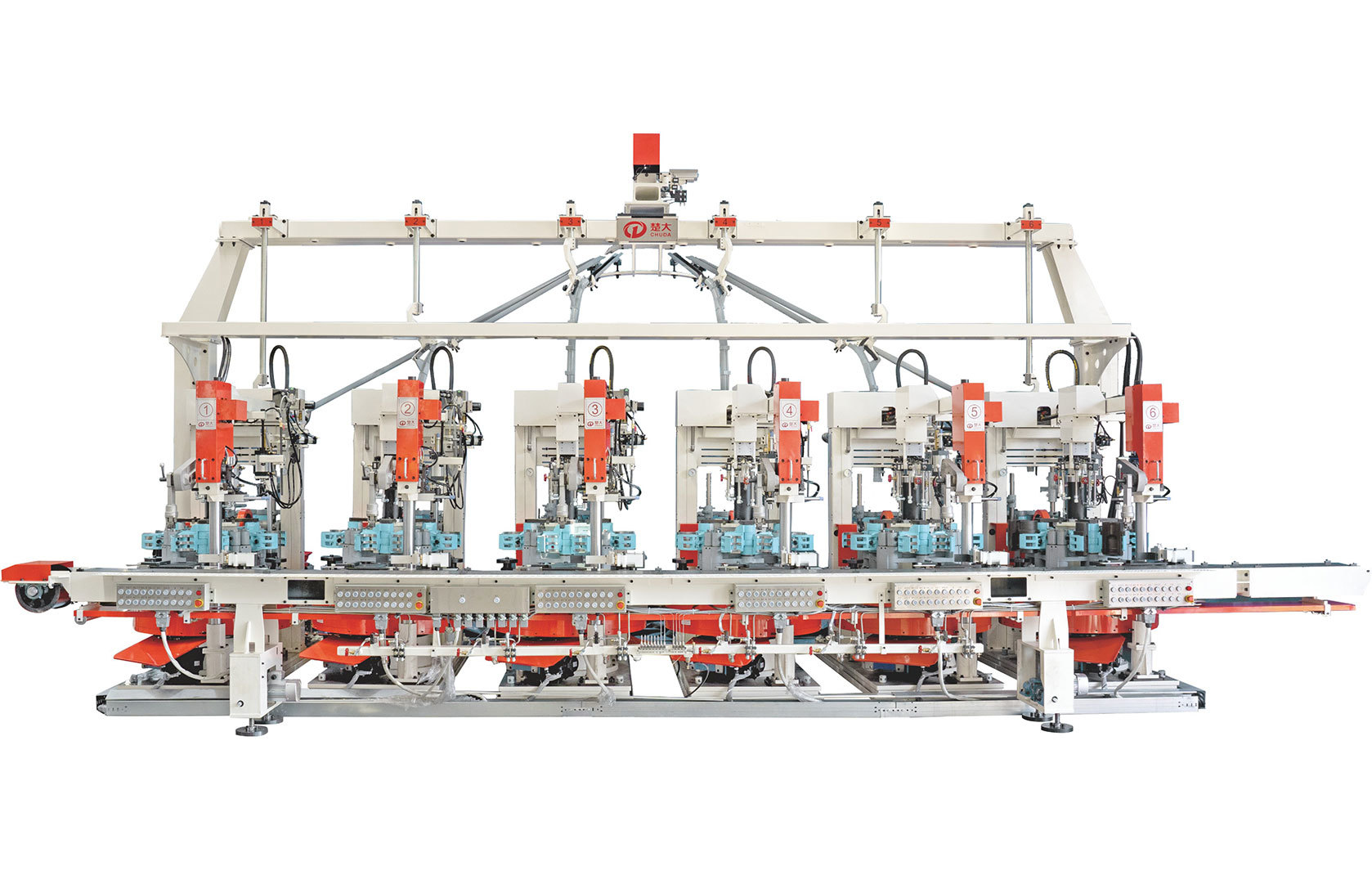

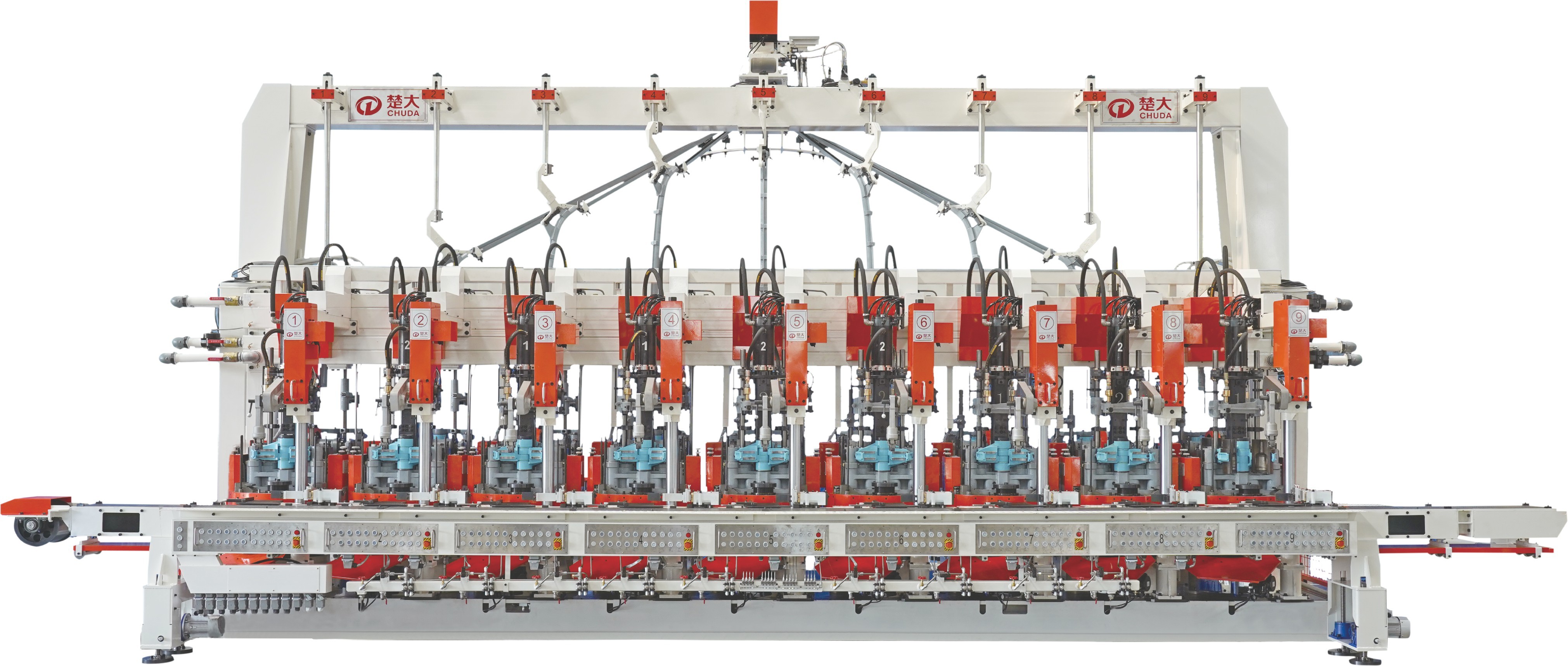

CBGW-ⅡSG/DG

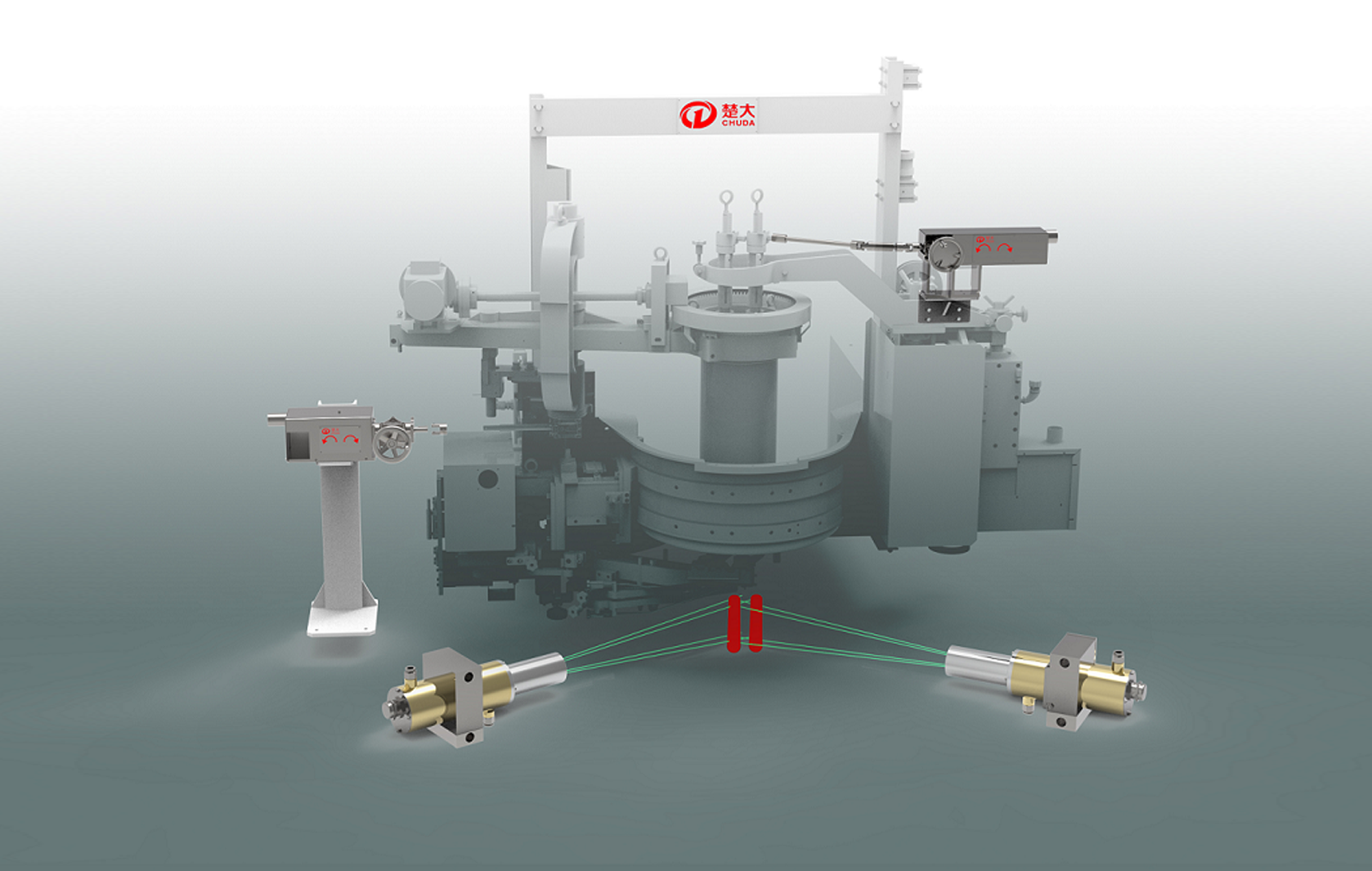

WORKING PRINCIPLE

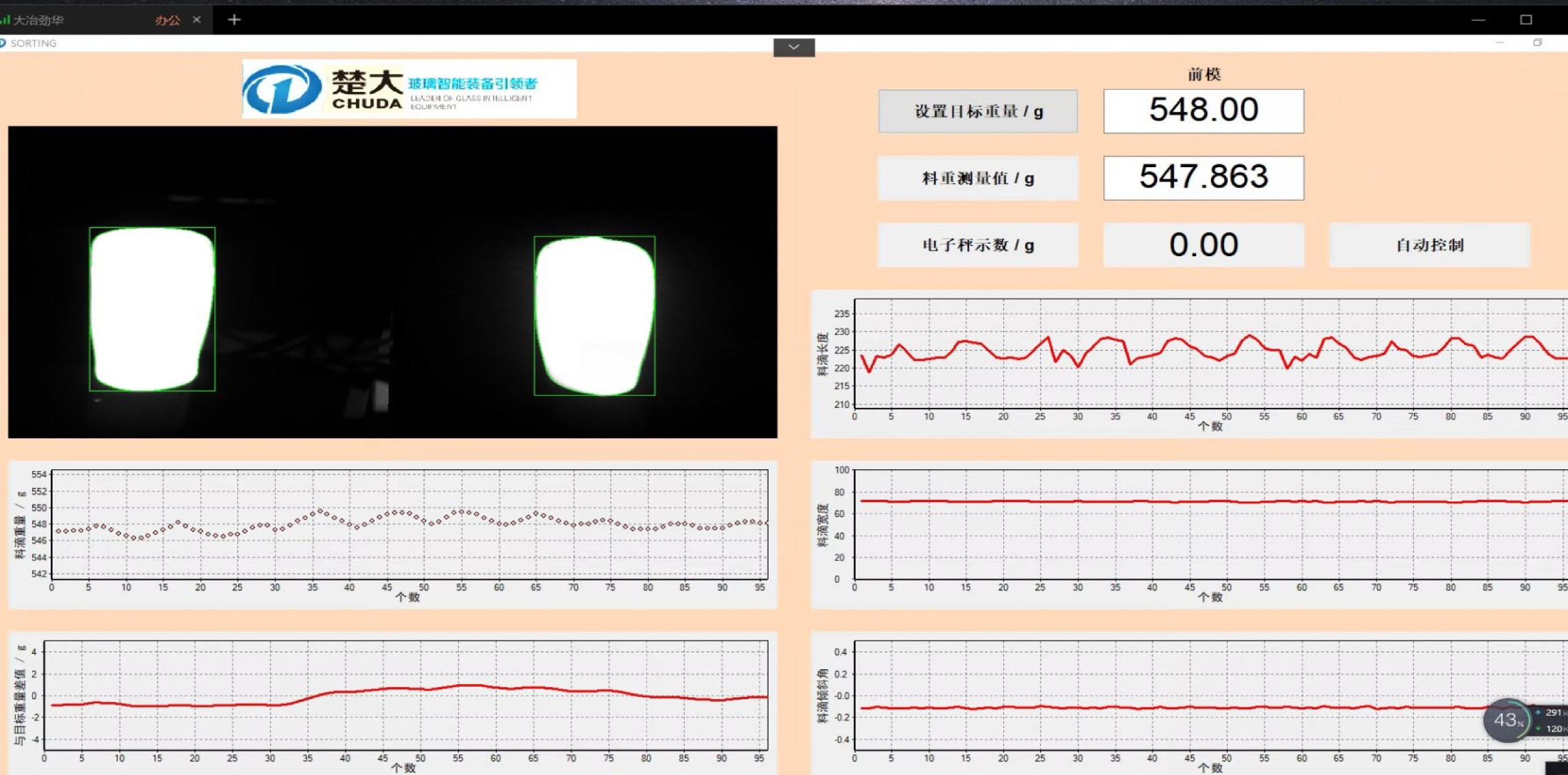

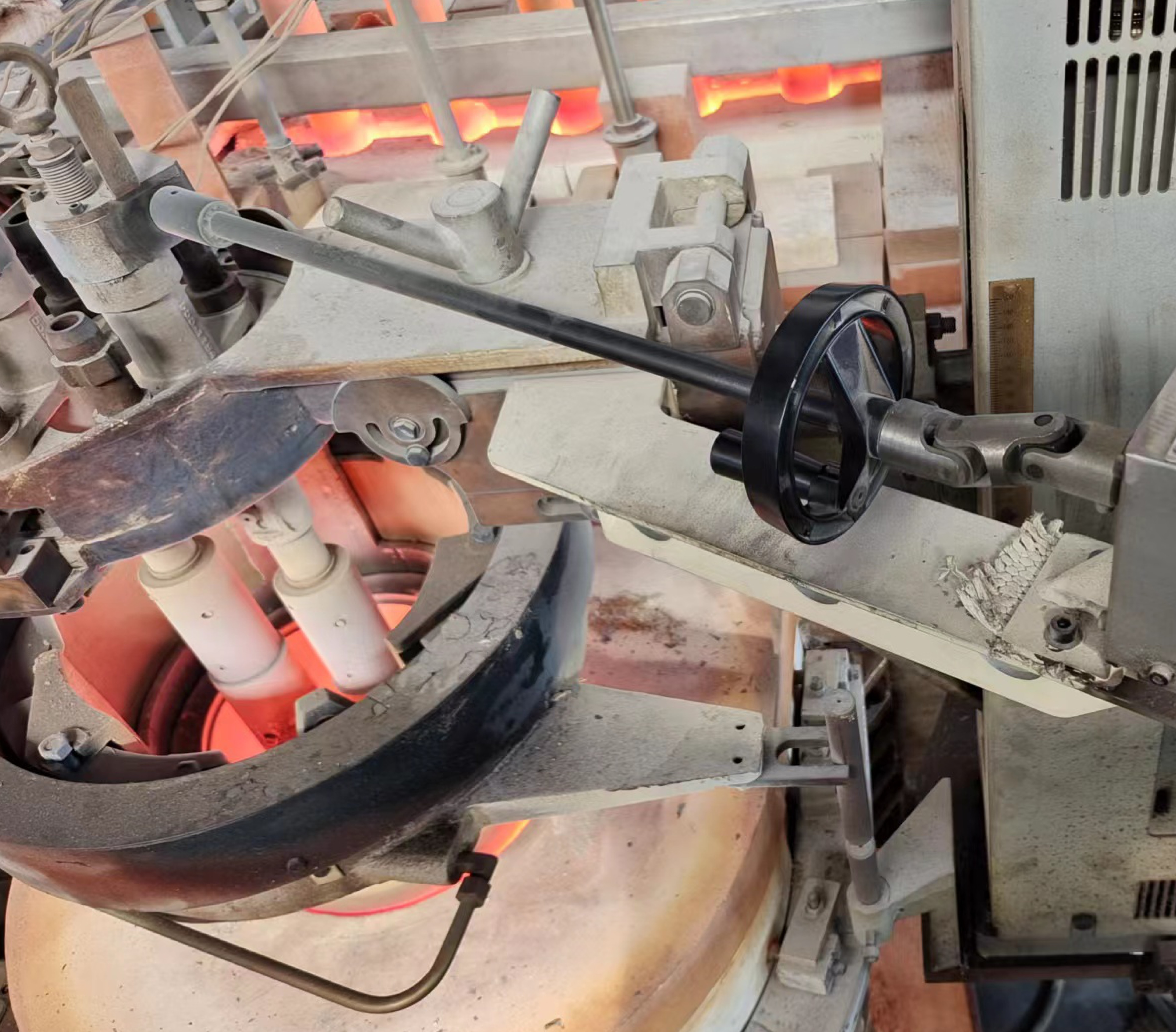

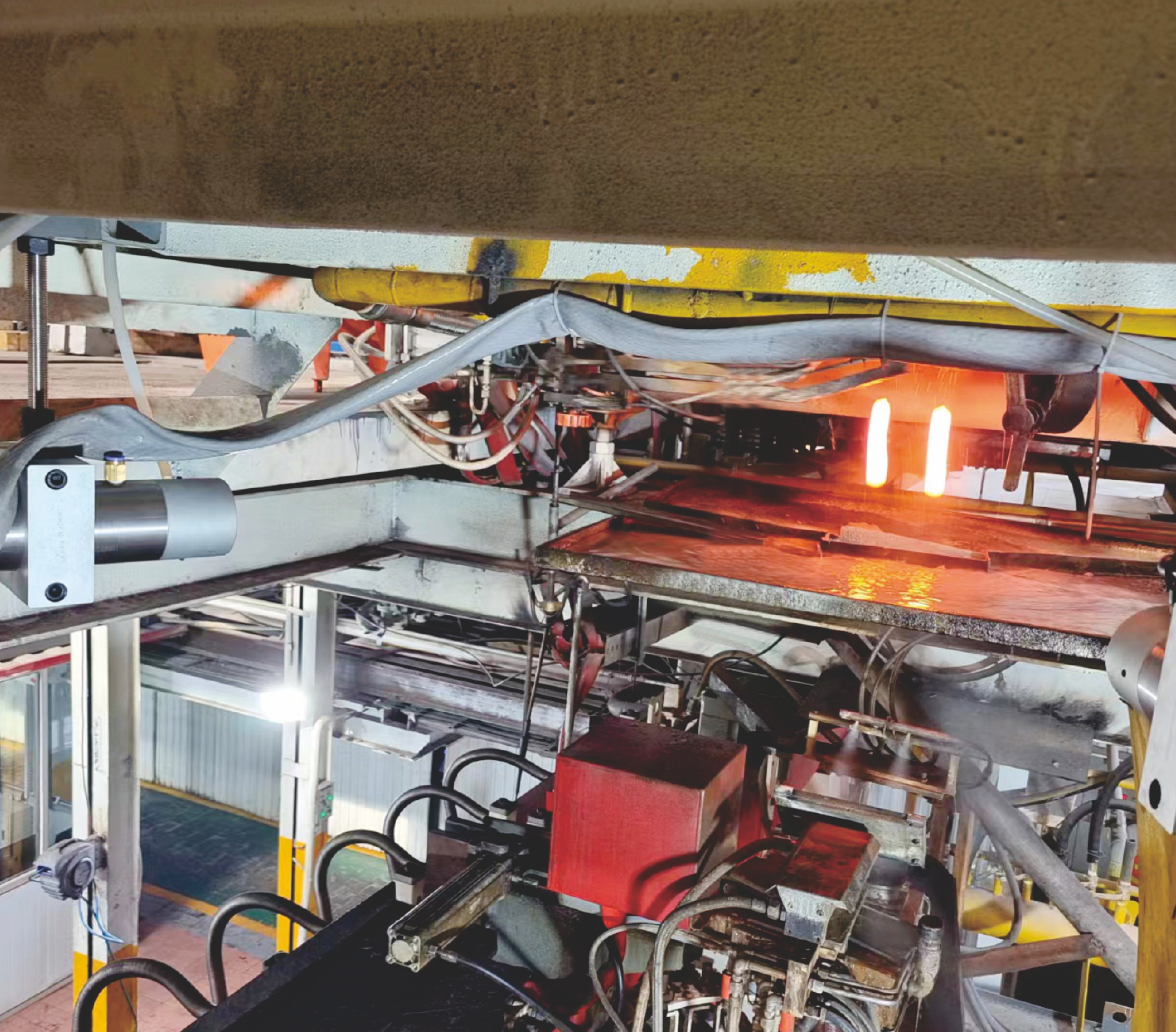

双目视觉料重控制系统CBGW是通过两台新一代高清相机来完成料滴实时连续拍摄,从不同的两个角度获取料滴的长度、直径、速度、角度及料滴缺陷等参数,实现对料滴3D数学建模后计算得到当前料滴的重量,通过伺服系统控制匀料筒和冲头的高度来实现自动控制料滴重量与料形。

The camera-based gob weight control system(model: CBGW) adopts dual HD cameras to generate images

of glass gobs, and obtain measurements such as length, diameter, speed, angle and defects of the gob from

two different angles. Then geometric data of the digital 3D models can be calculated before acquiring the

current gob weight, as well as automatically control the gob weight and shape by controlling the height of

the tube and plunger.

FEATURES & ADVANTAGES

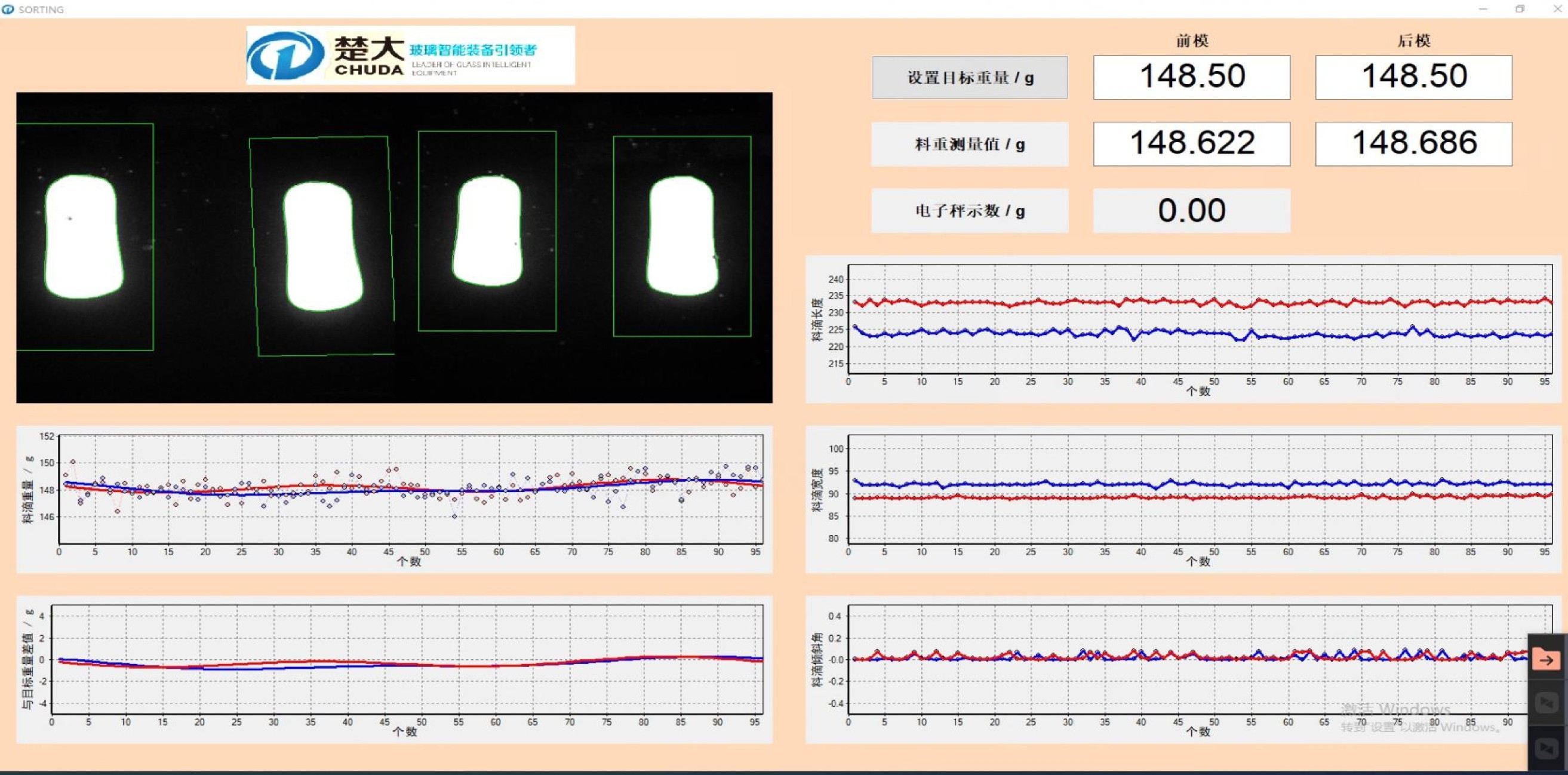

|

☑ |

实现对料形、料重24小时实时闭环自动控制,连续闭环监控,料重控制精度可达:±0.5g,能满足NNPB、 BB、PB成型工艺要求。 |

|

|

Real-time closed-loop automatic control and monitoring of gob shape and weight. The control precision of gob weight can reach to ±0.5g, which is applicable to NNPB/BB/PB process requirements. |

|

|

|

|

☑ |

高清视觉相机速度可达600张/分,能满足单滴、双滴、三滴制瓶机最高1800个/分机速生产。 |

|

|

The speed of the HD camera can reach 600 images/min, which can meet the maximum production speed of 1800 images per minute for single gob, double gob, and triple gob machines. |

|

|

|

|

☑ |

系统具备对料滴长度、直径、摆角自动检测,对不合格料形预期报警,超差的料重能对制瓶机执行剔瓶功能。 |

|

|

The system can automatically detect the length, diameter and swing angle of the gob, and give an alarm for the unqualified gob shape, also capable to perform bottle rejecting if the gob weight is out of tolerance. |

|

|

|

|

☑ |

触摸屏操作界面,直观简便,能快速完成从手动到自动转换,换产调试简便快捷。 |

|

|

Intuitive HMI interface, easy to operate, fast job change and commissioning. |

|

|

|

|

☑ |

异常情况自动声光报警,提醒用户异常状况采取处理。 |

|

|

Automatic sound and light alarm in case of abnormal situation, which remind users to take timely measures. |

|

|

|

|

☑ |

现场定时校称提醒功能,只需按制定先后顺序放瓶称量即可,无须其它任何操作。 |

|

|

On-site regular scale calibration reminder, put the bottles in the established order and weigh, no other operations required. |

|

|

|

|

☑ |

系统检测实时图像数据可建立数据库,可根据需要提取监控数据进行工艺分析。 |

|

|

The real-time image data detected by the system can generate a database, and the monitoring data can be extracted for process analysis. |

|

|

|

|

☑ |

具有稳定工艺,提高质量,提升效率,降低成本,增加效益的目的和意义。 |

|

|

Stable production process, improved quality and efficiency, cost reduced and benefit increased. |

|

|

|

|

|

|

|

|

Online Inquiry

If you have any suggestions or feedback on our service, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.

WeChat Public Number

Hubei Chuda Intelligent Equipment Co., Ltd.

Telephone:0724-2498136

E-mail:fiona@chuda.cn

Production Base: No.1 Jingnan Avenue, Duodao District, Jingmen City, Hubei Province

Copyright: Hubei Chuda Intelligent Equipment Co., Ltd. This website has supported IPV4 / IPV6 bidirectional access

Website construction:China Enterprise Power Yichang

SAF Coolest v1.3 设置面板 MPFSX-ZHXV-UQAAE-ZXF

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page